Marlon CST

Marlon CST corrugated multiwall polycarbonate sheet provides all the durability and impact resistance of corrugated polycarbonate sheet with the added insulation and rigidity provided by the multiwall structure. Co-extruded UV protection provides resistance against the effects of UV weathering. Marlon CST can be used with fibre cement sheeting or as a complete roof and wall cladding material.

Marlon CST is also available in Marlon BioPlus, the ideal choice for projects that aim to deliver the highest standards in sustainability, allowing companies to demonstrate they are at the forefront of the low carbon circular economy.

Marlon BioPlus is made with a bio-circular attributed resin in which 89% of the fossil based raw material has been replaced by renewable hydrocarbons e.g. from used cooking oil, which dramatically reduces the impact of the finished sheet on the environment, whilst maintaining the same material properties and ease of processing.

Use our Profile Finder Tool to search for a profile.

Key features

- Light in weight

- Enhanced spanning capabilities

- Reduced condensation from multiwall structure

- Damage and impact resistant

- Available in Marlon BioPlus

Applications

- Industrial rooflights and canopies

- Vertical glazing

- Greenhouses and farm buildings

- Pergolas and patio covers

- Multiwall structure reduces condensation

- Damage & impact resistant

- Optically clear

- Excellent structural durability

- Thermally insulating

- Easy to handle & install

- Co-extruded UV protection

- Excellent fire performance

- Limited warranty

| Thicknesses: | 2.5 Twinwall and 6mm Triplewall |

| Colours & tints*: | Clear, glass clear, pearlescent, heatguard, specials |

| Finishing options: | Mitred corners, heat sealed edges |

| Other options*: | Double sided UV protection, available in Marlon BioPlus |

| Colour | 2.5mm Twinwall | 6mm Triplewall |

| Clear | 82% | 79% |

| Glass clear | - | 77% |

| Pearlescent glass | - | 53% |

| Opal | - | 38% |

- Marlon CST is a high quality, extruded, corrugated multiwall polycarbonate sheet with a co-extruded UV resistant coating

- As polycarbonate is a thermoplastic, it is important to take thermal expansion and contraction into account during any installation process.

- Marlon CST has been independently tested to various Fire Standards; for the most current certification please contact our Technical Department.

- Marlon CST is REACH and RoSH compliant, and 100% recyclable

- Any colour option is a through-colour so the colour of a cut edge will match the colour of the surface.

- Marlon CST sheets are covered by a limited warranty. For full details contact our Technical Department.

Storage & sheet preparation

- Store sheets on a flat surface. Use an opaque cover, tightly secured, to protect from wind, rain and sun. Storage is always preferable indoors.

- Ensure that the clearly marked UV protected surface of the Marlon CST sheet is to the outside.

- Marlon CST sheets must always be installed with the corrugation running vertically, or up-slope.

- Roofs should always be designed with a minimum slope of 5° to allow adequate rainwater run-off.

- Marlon CST sheet can be cut with a fine tooth circular saw or hand saw at a shallow angle.

Thermal movement & fixing

Important - polycarbonate sheet will expand in the heat and contract in the cold.

- When drilling fixing holes they must be oversized to allow the sheet to move.

- Fixing holes should be drilled 6mm greater in diameter than the fixing shank for sheet lengths up to 2m and an additional 3mm per additional meter length of sheet. E.g. for a 4m long sheet, holes should be over drilled by 12mm

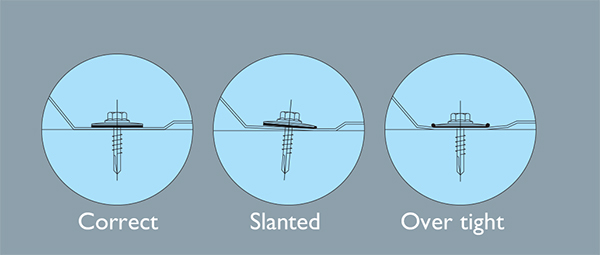

- Fixings must not be overtightened, again this allows the natural movement of the sheet and will avoid unnecessary damage to the sheet.

- Marlon CST sheet must be isolated from plastisol and flexible PVC paints and coatings using an aluminium barrier tape.

- If installing onto fibre cement sheets ensure that all dust created when drilling holes is removed.

Other considerations

- Ensure that all sealants and tapes are compatible with Polycarbonate.

- Ensure mitres on Marlon CST and fibre cement sheets correspond.

- Use Marlon CST sheets of equal length to the fibre cement sheets on a roof.

- Proper purlin spaces MUST be maintained appropriate to loading.

- Sealants and washers on fasteners MUST be compatible with polycarbonate and should preferably be white in colour.

- The sheet should be supported with foam fillers at each purlin position.

- Marlon CST is NOT suitable for curved roof applications.

- Fasteners must be fitted with a 25mm EPDM bonded washer (BAZ washer).

- Clean away all dust created when drilling holes in fibre cement sheets.

- Primary fasteners must be fixed through each crown at top and bottom end laps, and through alternative crowns on intermediate purlins

- When installing any roofing material, including rooflights, ensure that safe working methods are adopted and appropriate safety equipment is used.

As a condition of ensuring that Marlon CST sheets perform at optimum throughout their service life and retain light transmission properties, it is recommended that the sheets be cleaned periodically using suitable household cleaning agents as follows:

- Use lukewarm water to rinse the sheet and soften dirt.

- Make up a solution of lukewarm water and ordinary household cleaner or a mild soap and use this to wash the sheet.

- A sponge or soft cloth should then be used to gently remove dirt and grime.

- The cleaning process should then be repeated and the sheet rinsed and dried with a soft cloth.

WARNING

Care should be taken to observe the following precautions:

- Do not scrub Marlon CST sheet with brushes or sharp instruments.

- Never steam clean, use low pressures for pressure washing.

- Avoid any abrasives or cleaners of a highly alkaline composition.

- It is generally advisable in all instances to test any cleaner on a sample piece of the Marlon CST sheet first and it should also be remembered that cleaners and solvents which state that they are suitable for cleaning polycarbonate may not be safe for use on the UV protective surface of the panels.