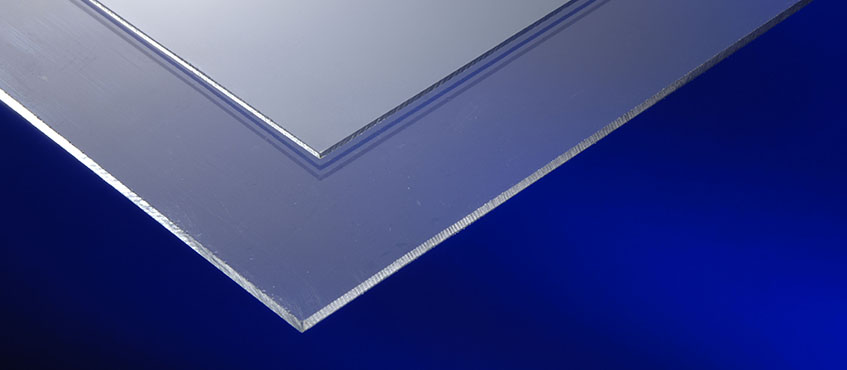

Polystyrene is a cost effective option for many industrial and DIY applications. Brett Martin’s Styrene flat sheet is used for glazing and DIY.

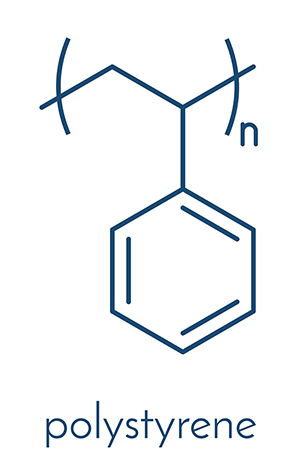

In 1839, German chemist Eduard Simon discovered polystyrene by isolating a substance from natural resin. However it was not until 80 years later that another German chemist, Hermann Staudinger, realised that the isolated chemical was, in fact, a plastic polymer made up of long chains of styrene molecules. He named it polystyrene.

Foamed polystyrene was developed under different brand names during the 1940s and 50s. It is made from the polymerisation of the monomer styrene and has the chemical formula is (C8H8)n.

It is made from the polymerisation of the monomer styrene and has the chemical formula is (C8H8)n.

Polystyrene can be extruded, injection moulded or blow moulded.

Extruded polystyrene is made from molten polystyrene pellets which are passed through a die and cooled rapidly to form sheets.

Foamed polystyrene is produced using “blowing agents” that expand and cause the foam to form in a state such that it is principally composed of trapped air.- Lightweight

- Transparent

- Good electrical insulator

- Economical

Rigid polystyrene can be used in the following applications:

- Test tubes and petri dishes

- CD cases

- Smoke detectors

- Rigid food trays and containers

- Disposable cutlery, plates and bowls

- Internal glazing and partitions

- Picture framing

- Lightweight shelving

Brett Martin manufactures and sells rigid polystyrene which it refers to as Styrene to avoid confusion with the more commonly known expanded polystyrene.

Plastics Industry

British Plastics Federation www.bpf.co.uk

The Plastics Portal www.plasticseurope.org

Associations

European Plastic Distributors Association www.epda.com

International Association of Plastics Distributors www.iapd.org